Steel Metal Processing Briquetter for Recycling Industries

$68000-74000 /Set/Sets

| Payment Type: | T/T |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean |

| Port: | Shanghai |

$68000-74000 /Set/Sets

| Payment Type: | T/T |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean |

| Port: | Shanghai |

Model No.: Y83W-630

Brand: Zhouzhuang

Place Of Origin: China

Status: New

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Ordinary Product

Warranty Period: 1 Year

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Quality: Iso9001:2008

Place Of Origin: Jiangsu, China

Condition: New

Press Force: 6300kn (630ton)

Operation: Siemens Plc Automatic

Work Efficiency: 3~4 Block/Minute

Chiller: Water Cooler Or Air Chiller

Machine Weight: About 16ton

Motor Power: 30kw*3

Shift Efficiency: 14-16ton/Shift (8 Hours)

Improve your bottom line and reduce waste by compacting scrap metal in a hydraulic Briquetting Machine from Ecohydraulic. With our briquetting machines, you can transform industrial turnings, filings, chips, chippings and even metallic dust from copper, brass, aluminum and other metals into compressed briquettes worth more than non-compacted scrap metal.

With our briquetter options to choose from among our foundry and industrial series equipment, you're sure to find the right briquetting machine for your company's scrap metal processing and recycling needs.

Product description

1) product application

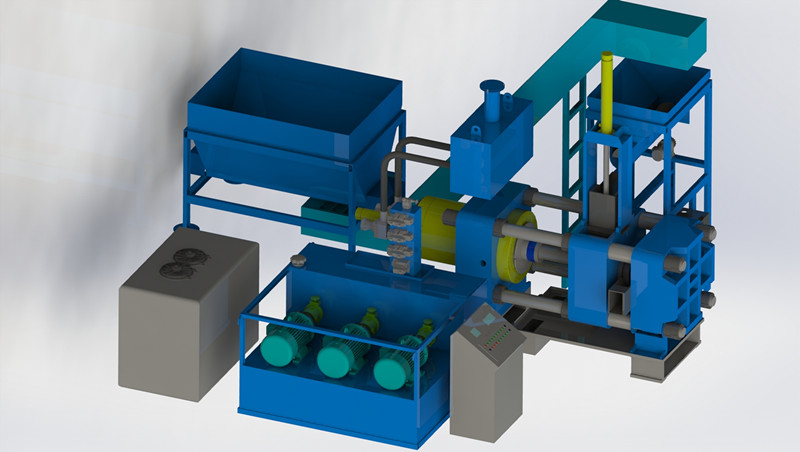

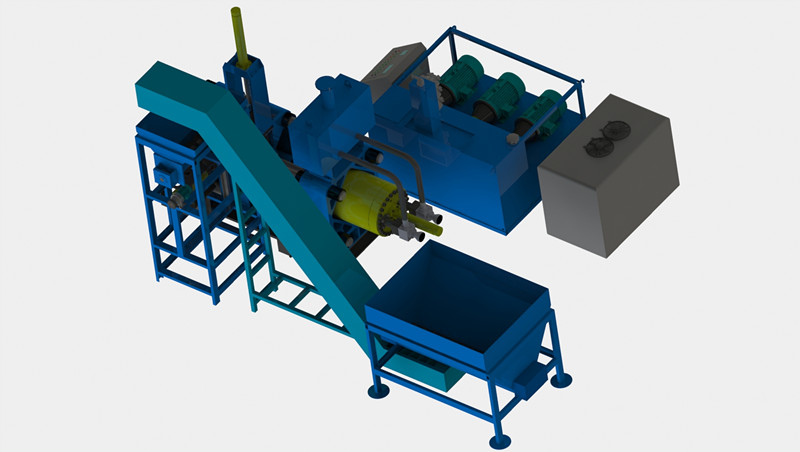

The Y83W series Horizontal Briquette Machine is industrial machine designed to press metal chips into briquettes and operate in automatic mode.

2) pressed materials

cast iron, aluminum, copper, steel, brass, zinc, bronze, titanium, magnesium and other metal scraps.

3) advantages

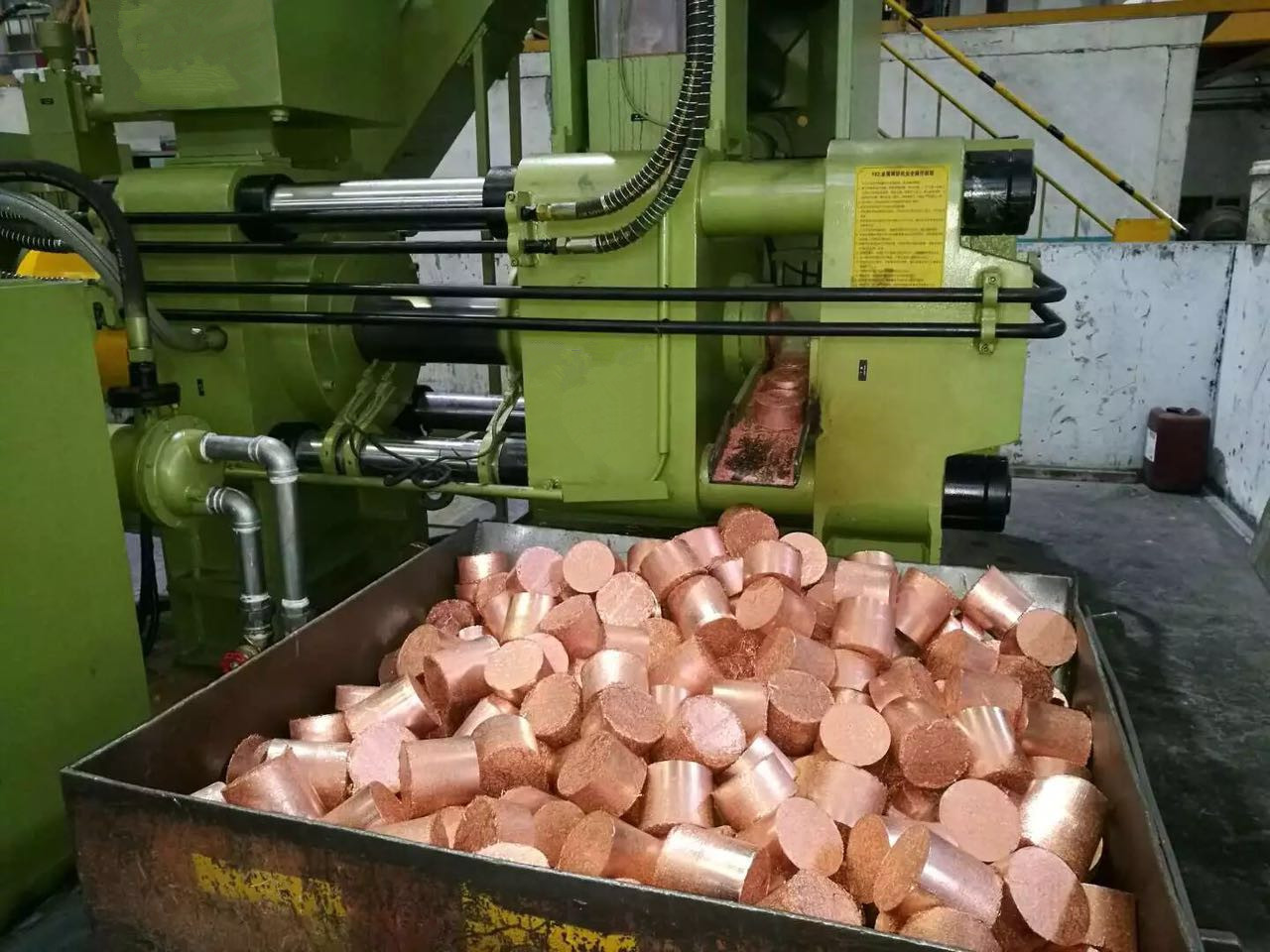

- the high pressure reached in the compression chamber allows creating high density briquettes.

- besides drastically reducing the volume of the machining chips, remove cutting fluids and create briquettes.

- in most cases, briquettes can be placed directly in smelting furnaces.

- this results in substantial economic benefits for companies that generate the scraps, companies that recycle metal scraps, and for foundries that process the scraps.

- there are a large number of environmental benefits resulting from the briquetting process.

4) Steel Briquetter parameters

model Y83W-630 nominal force 6300kn briquette diameter D150 (customized) briquette density ≥ 5.2t/m³ briquette weight 12~15kg productivity 3block/min output in one shift 14~16t/8h total power 30kw*3 machine weight about 16ton overall dimension host machine: 5000*2250*2550mm

oil tank: 2150*1600*1460mm

Factory introduction

1) Overview

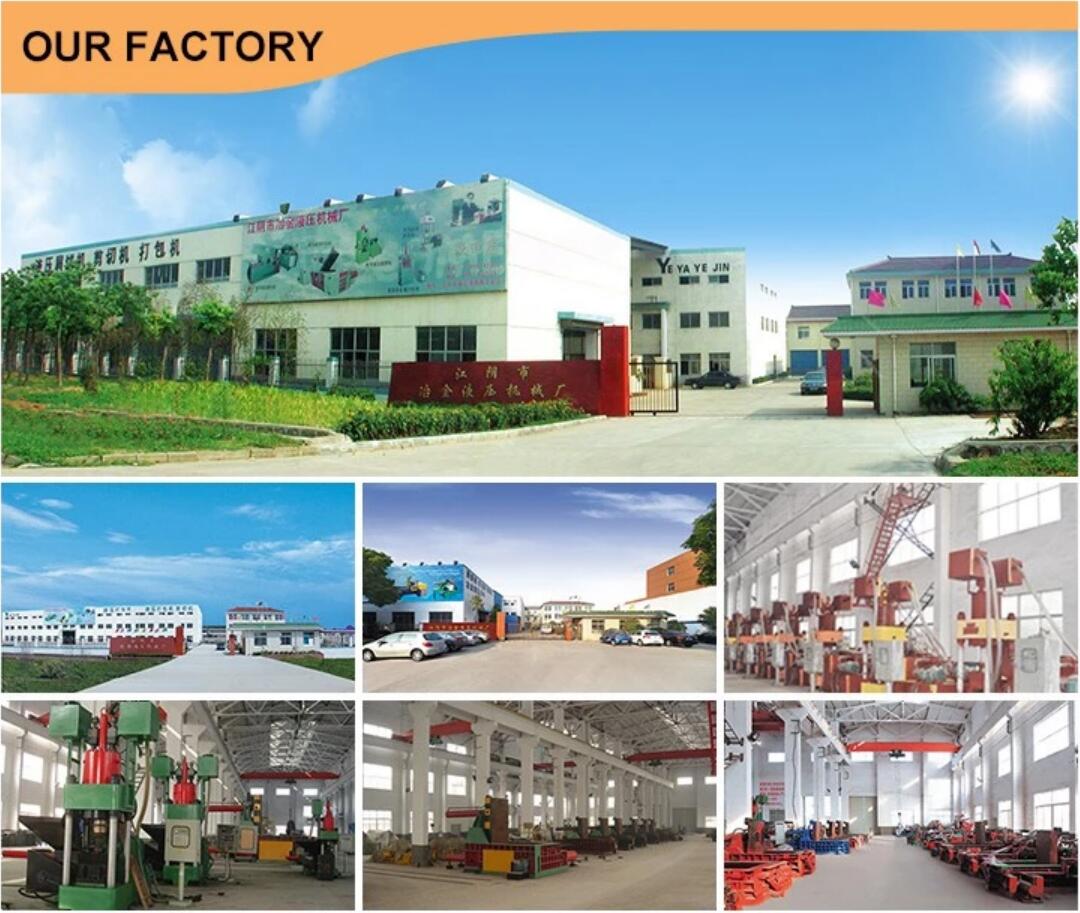

Jiangyin Metallurgy Hydraulic Machinery factory (brand name : ECOHYDRAULIC) was originally set up in 1997(Founder Mr.Ge originally involved in hydraulic R&D activity in 1989) to manufacture and market Briquetting Press, metal balers, alligator shears, metal shears and other non ferrous scrap processing equipment. During the last three decades we have installed over 3000 systems , build the entire quality controlling standards and cultivated an experienced technique & after sales team. Why ECOHYDRAULIC? Since 1987, the ECOHYDRAULIC brand has been a trusted name in domestic metal recycling with commitment to economic value, sustainability, safety and customer satisfaction. Our product covered all states in China and over 23 countries including USA, Japan, Russia, Europe, South Asia and Middle East. Currently, we have two plants over 12000 square meters. There are more than 80 staff members, 12 professionals among them. We build over 200 machines annually. And now, proudly, we clearly build our vision : grow up with our customers. And our mission : the most professional ,economic,reliable supplier in the industry.

2) Our team

1) Free product documents translation into your language, worry-free to operate and maintain.

2) Engineers available to service machinery overseas.

3) Customer datebase with all customers' records in it.

4) 7*24 technical phone service.

5) One year guarantee and lifelong maintenance.

6) Spare parts: Supply one set of spare parts for free, tool box, operation book.

3) Our exhibition for Steel Chips Briquette Machine

Packaging&Delivery for Steel Shavings Briquette Machine

Packaging detail: Multiple protection methods in order to lower risks during delivery process, normally nude packing.

Shipping detail: 30 days.

Save your money from briquetting

Steel

Whether it's turnings, chips, filings, shavings or sludge, the steel you use is being wasted as it gathers on your shop floor, Steel Briquetting Press can double the value you get for your steel scrap compared to loose chips or other recycling methods.

Aluminum

Aluminum scrap metal, in the form of turnings, filings, chips and shavings, piling up on the equipment and floor, taking up the valuable floor space, squeeze value from aluminum waste, compress aluminum scrap into dense briquettes and separate any fluids used in the metalworking process from the scrap metal.

Copper

What do you do with your copper scrap? If you are like Many manufacturers, the scrap is stored in your yard, then hauled away (at your expense) to be disposed of, it's time to turn copper waste into an asset. Ecohydraulic briquetting press turns your scrap copper into compressed briquettes that are easier to handle, store and transport and can be sold for recycling.

Contact us! We would like to tell you more about our Steel Briquette Machine.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.